Thermal Stress And Thermal Strain

Thermal stress and thermal strain are crucial concepts in material science, referring to the deformation and internal forces that arise within a material when it experiences changes in temperature. When an object is heated or cooled, its dimensions change, but if these dimensional changes are constrained, internal forces develop, leading to thermal stress. This phenomenon is common in everyday life, such as when bridges expand and contract with temperature changes, leading to potential cracks or structural fatigue. Similarly, in electronic devices, thermal stress can cause components to fail if not properly managed. Understanding these effects is essential for designing materials and structures that can withstand temperature fluctuations without compromising their integrity.

This Story also Contains

- Thermal Stress and Thermal Strain

- Solved Examples Based on Thermal Stress and Thermal Strain

- Summary

Thermal Stress and Thermal Strain

Thermal stress and thermal strain are essential phenomena that occur when materials undergo temperature changes, leading to expansion or contraction. When a material is heated, it tends to expand, and when cooled, it contracts. However, if the material is restrained or the temperature change is uneven, this can result in internal forces known as thermal stress. Thermal strain, on the other hand, refers to the deformation or change in dimensions of the material due to this stress. These concepts are vital in engineering and construction, as they help explain why bridges, railways, and buildings must be designed to accommodate temperature variations.

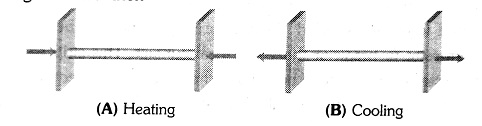

Thermal Stress in a Rod Which is Rigidly Fixed

When a rod is rigidly fixed at ends such as to prevent expansion or contraction when its temperature is increased or decreased. Due to preventing its thermal expansion or contraction, compressive or tensile stress is developed in it. As the rod tries to expand or contract, then it applies a reaction force on the rigid support. If the change in temperature of a rod of length L is $\Delta \theta$ then

Thermal strain $=\frac{\Delta L}{L}=\alpha \Delta \theta \quad\left[\right.$ As $\left.\alpha=\frac{\Delta L}{L} \times \frac{1}{\Delta \theta}\right]$

If we know the strain then with the help of Hooke's law, we can find the stress also. If we know the stress, then we can find the force by multiplying the cross-sectional area with stress. Both stress and force can be written as -

So, Thermal stress $=Y \alpha \Delta \theta$

or, Force on the supports $F=Y A \alpha \Delta \theta$

Recommended Topic Video

Solved Examples Based on Thermal Stress and Thermal Strain

Example 1: A metal rod of young modulus Y and coefficient of thermal expansion $\alpha$ is held at its two ends such that its length remains invariant. If its temperature is raised by $t^{\circ} \mathrm{C}$ the linear stress developed in it is

1) $\frac{Y}{\alpha t}$

2) $Y \alpha t$

3) $\frac{1}{Y \alpha t}$

4) $\frac{\alpha t}{Y}$

Solution:

Thermal Stress

When a rod whose ends are rigidly fixed such as to prevent expansion or contraction.

wherein

$\operatorname{strain}=\frac{\Delta l}{l}=\alpha \Delta T$

Hence, the answer is the option (2).

Example 3:

A metal rod of young modulus Y and coefficient of thermal expansion $\alpha$ is held at its two ends such that its length remains invariant. If its temperature is raised by $t^0 \mathrm{C}$ the linear stress developed in it is

1) $\frac{Y}{\alpha t}$

2) $Y \alpha \DeltaT$

3) $\frac{1}{Y \alpha t}$

4) $\frac{\alpha t}{Y}$

Solution:

$

\text { Strain }=\frac{\Delta l}{l}=\alpha \Delta T

$

And Thermal stress $=\mathrm{Y} .($ Strain $)=Y \alpha \Delta T$

Hence, the answer is the option (2).

Example 4: A wooden wheel of radius R is made of two semicircular parts (see figure); The two parts are held together by a ring made of a metal strip of cross-sectional area S and length L. L is slightly less than $2 \pi R$ To fit the ring on the wheel, it is heated so that its temperature rises by $\Delta T$ and it just steps over the wheel. As it cools down to the surrounding temperature, it presses the semicircular parts together. If the coefficient of linear expansion of the metal is $\alpha$ and its Youngs' modulus is Y, the force that one part of the wheel applies on the other part is :

1) $2 \pi S Y \alpha \Delta T$

2) $S Y \alpha \Delta T$

3) $\pi S Y \alpha \Delta T$

4) $2 S Y \alpha \Delta T$

Solution:

Increase in length $\Delta L=L \alpha \Delta T$

$

\therefore \quad \frac{\Delta L}{L}=\alpha \Delta T

$

The thermal stress developed is

$\begin{aligned} & \frac{T}{S}=Y \frac{\Delta L}{L}=Y \alpha \Delta T \\ & \text { or } T=S Y \alpha \Delta T\end{aligned}$

From FBD of one part of the wheel

or F = 2T

Where F is the force that one part of the wheel applies on the other part.

$F=2 S Y \alpha \Delta T$

Hence, the answer is the option (4).

Example 5: A force of 20N is applied at one end of a wire of length 2m and has an area of cross-section $10^{-3} \mathrm{~m}^2$. The other end of the wire is rigidly fixed. Its coefficient of linear expansion of the wire is $\alpha=5 \times 10^{-7} /{ }^{\circ} \mathrm{C}$ and Young's modulus $y=2.2 \times 10^9 \mathrm{~m} / \mathrm{m}^2$ and if its temperature is increased by $5^{\circ} \mathrm{C}$ then the increase in the tension of the wire will be.

1) 4.2 N

2) 4.4 N

3) 2.4 N

4) 8.8 N

Solution:

$\begin{aligned} & \text { Increase in the tension of the wire }=Y A \alpha \Delta \theta \\ & \qquad \begin{aligned} & =2.2 \times 10^{11} \times 10^{-2} \times 8 \times 10^{-6} \times 5 \\ & =8.8 \mathrm{~N}\end{aligned}\end{aligned}$

Hence, the answer is the option (4).

Summary

Whenever a material is subjected to a rise or fall of temperature, in which it expands or contracts but is constrained in such a way that the material cannot move freely then it undergoes thermal stress. This constraint has the effect of causing internal forces, which, in turn again, produce the stress within a material. Thermal strain is like a process of deformation or change in shape in the material due to the above-mentioned stress. Engineering and construction have both thermal stress and strain as their concern because they can result in material fatigue, cracking, or failure. For example, it is necessary to design bridges, buildings, and pipes with regard to thermal expansion and contraction to avoid damage. Understanding these phenomena aids engineers in constructing safer and more solid structures that might confront these temperatures variably.